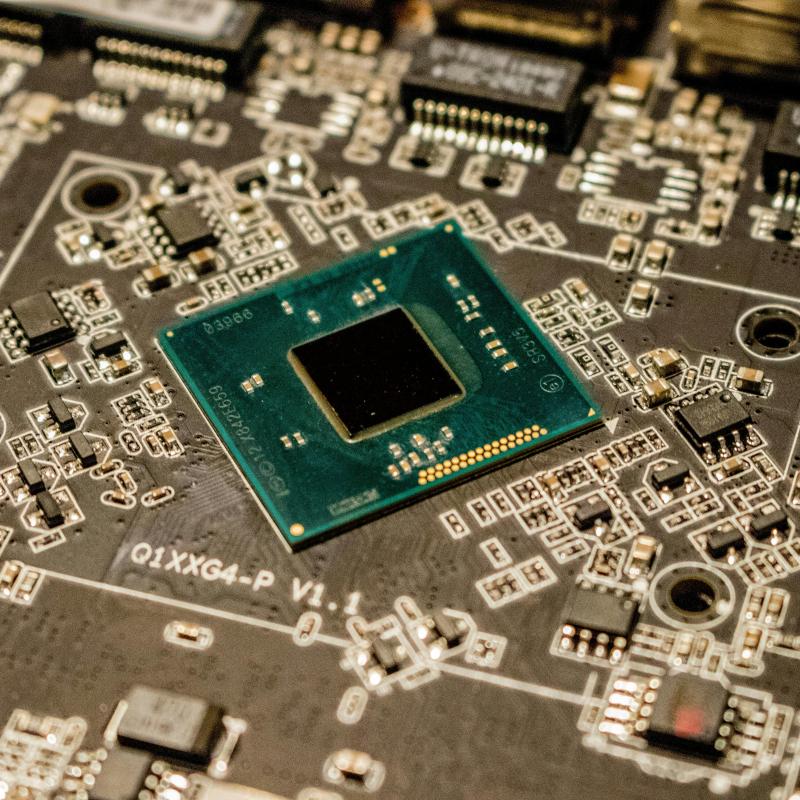

PPC Solvent Recovery Rotor

PPC Low-Temperature Regeneration Rotor Specifically designed for low-temperature regeneration, it significantly reduces energy consumption in systems operating at lower regeneration temperatures.

The PPC rotor is engineered to deliver superior dehumidification performance at low regeneration temperatures, featuring an integrated activated carbon layer to prevent cross-contamination. These characteristics make the PPC rotor an ideal choice for passive dehumidification and energy recovery systems.

Energy Synergy Technology

Utilizes waste heat from refrigeration for rotor regeneration, maximizing the efficiency of hybrid (refrigeration + dehumidification) systems.

Dual-Effect Material

- Advanced Silica Gel: Specially formulated desiccant material that is less prone to wash-out and offers higher adsorption capacity under high relative humidity.

- Activated Carbon Layer: Effectively adsorbs volatile organic compounds (VOCs) and eliminates cross-contamination.

ProFlute rotors are widely used in the following industries:

Highest desiccant content

The PPC rotor has a very high, 82%, active Silica Gel content. It can be used for most environment and applications.

Unique moisture adsorption

The density of dry media ranges from 192 to 225 kg/m³, delivering even better dehumidification performance in high-temperature and high-humidity environments. There is no limit for how high relative humidity the PPC rotor can stand as long as the droplets are not introduced into the rotor during operation.

Water washable

The rotor can be washed in the water when the rotor is saturated in humid environment. The PPC rotor should be washed with weak non-alkaline detergent.

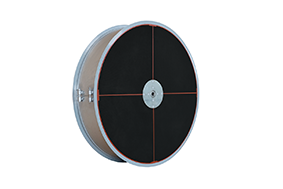

High surface strength

The surface compressive strength of the rotor media exceeds 100~150 kPa.

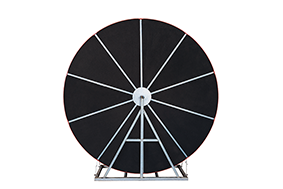

Variety in construction

The various kind of rotor construction could be made according to the customers' requirement, such as selection of raw material of the metal parts and with or without flange etc. For the large rotors, the knockdown construction will be very convenience for transportation and assembly on site.

Material composition

- Very high silica gel contents – 82%

- Low glass fiber contents – 15~20%

- Acrylic surface coating – remaining 2%

Technical properties

- No limit on high relative humidity (as long as no droplets are introduced in rotor during operation)

- Rotor can be washed in water (with weak non-alkaline detergent after saturation in humid air)

Physical properties

- Dry material density – ~240 kg/m3

- Water vapour adsorption capacity > 40%

- Surface compression strength > 100~150Kpa