Application Areas

Pharmaceutical Manufacturing

In the pharmaceutical industry, preserving the quality of raw materials and products during production, storage, and transportation depends on precise control of relative humidity. Products such as powders, tablets, capsules, and diagnostic strips are highly sensitive to airborne moisture. Exposure to excessive humidity can lead to loss of potency, reduced shelf life, and issues including clumping, mold growth, or breakage. These moisture-induced problems can further cause blockages in production equipment and pipelines, severely disrupting operations across manufacturing, transportation, and storage—resulting in unnecessary time and cost losses. All of these risks can be proactively prevented with a reliable dehumidification solution.

Wind Power

Whether for offshore, onshore, or near-shore wind farms, it is of utmost importance to protect wind turbines and related assets from the impacts of mold, corrosion, and electrical failures. Achieving this protection requirement relies on the stable support provided by industrial dehumidification equipment with desiccant rotors as its core components.

Lithium Battery and Electronic Producing

Lithium battery and electronic producing covers a variety of settings, from small laboratory environments to large - scale dry rooms. Regardless of the setting, stringent humidity control is a core prerequisite for producing high - energy batteries, and ambient humidity in the production area must be maintained below 1%.

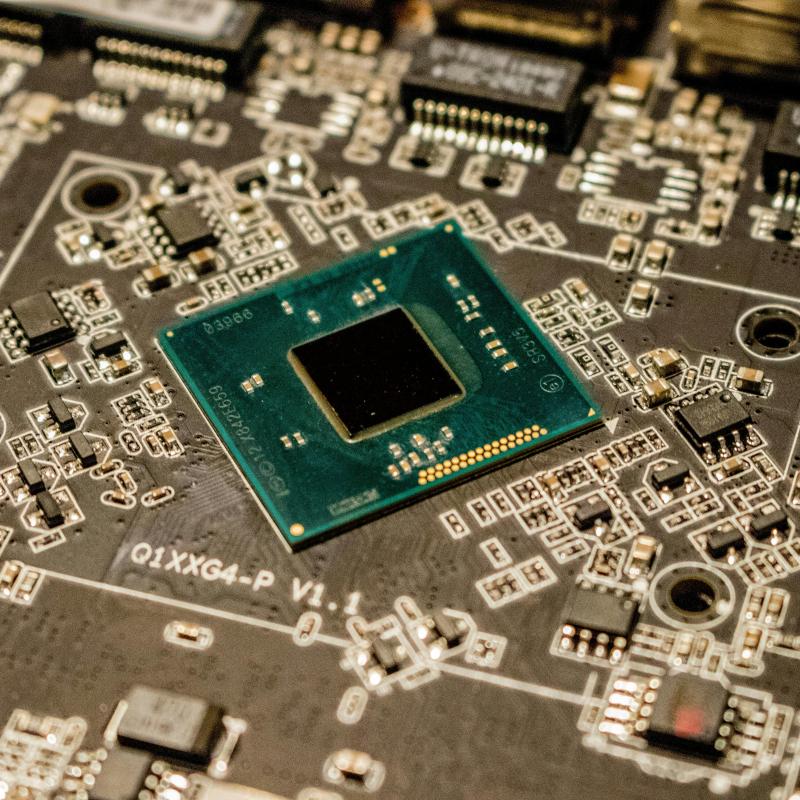

Semiconductor Processing

The entire process of semiconductor and electronic product manufacturing demands an extremely dry environment. Any instance of excessive humidity can trigger a chain reaction of issues, compromising both product quality and production efficiency.

Food Processing and Packing

Price and quality are the two core factors determining food sales. For food manufacturers, achieving competitive pricing through efficient production and cost - reduction measures is of utmost importance. Meanwhile, ensuring product quality necessitates particular attention to the air quality in the production environment. Only an environment with precisely controlled humidity can guarantee the consistent production of high - quality food products.

Ship Manufacturing and Bridge Corrosion Resistant

In marine and coastal climates, structures such as bridges and ship manufacturing facilities face continuous threats from humidity-induced corrosion. The combination of airborne moisture and salt causes severe corrosion problems, while persistent condensation further erodes structural components, compromising both service life and operational safety.

Plastic and Chemical Products Producing

Safe and efficient production of plastic and chemical products requires a stable manufacturing environment. A humidity control system equipped with ProFlute desiccant rotors helps maintain this stability throughout the year, enhancing product quality and safety while maximizing output and reducing unplanned downtime.

Storage and Maintenance for Military

Proper storage and maintenance are critical to preserving the operational readiness of defense equipment while controlling lifecycle costs. Dehumidification systems utilizing ProFlute rotors deliver reliable protection for military vehicles, weapons systems, and related assets worldwide.